Construction

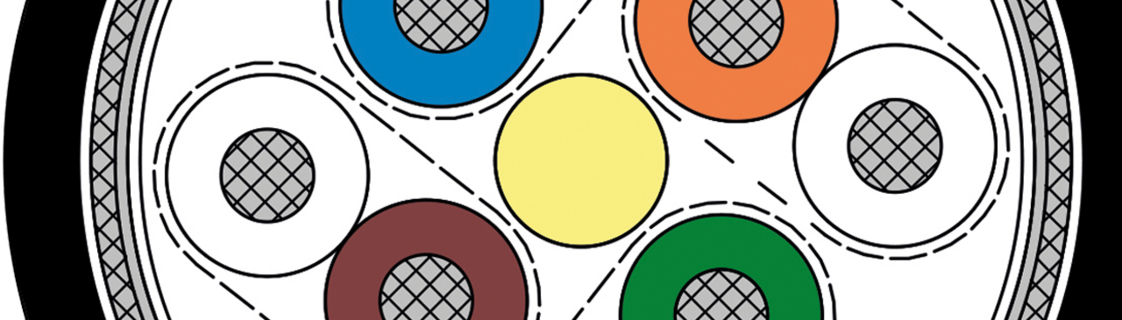

| Dimension | (4 x 2 x 22 AWG)C + 2 x 22 AWG |

|---|---|

| Conductor | bare copper strands, fine wires |

| Insulation | FEP |

| Colour code | CAT 5e: white/blue, white/orange, white/green, white/brown

22 AWG: black, brown |

| Stranding | Aramid in the centre, cores twisted to pairs, pairs in specially adjusted layering |

| Wrapping | foil |

| Screen | tinned copper braiding, optical coverage > 85% |

| Wrapping | tape |

| Sheath material | PUR |

| Sheath colour | black (similar RAL 9005) with mat surface, non-reflective |

(4 x 2 x 22 AWG)C + 2 x 22 AWG

bare copper strands, fine wires

FEP

CAT 5e:

white/blue, white/orange,

white/green, white/brown

22 AWG:

black, brown

Aramid in the centre, cores twisted to pairs, pairs in specially adjusted layering

foil

tinned copper braiding,

optical coverage > 85%

tape

PUR

black (similar RAL 9005)

with mat surface, non-reflective

Technical Data

| Peak operating voltage | max. 60 V |

|---|---|

| Testing voltage | core/core 600 V core/screen 600 V |

| Min. bending radius | fixed laying: 5 x d flexible application: 10 x d |

| Temperature range | fixed laying: -50/+90 °C flexible application: -40/+90 °C short-time use: +125 °C (2000 h) |

| Fire performance | flame retardant and self-extinguishing acc. to IEC 60332-1-2 + VDE 0482-332-1-2 |

| Oil resistance | very good - TMPU acc. to EN 50363-10-2 + VDE 0207-363-10-2 |

| Chem. resistance | good against acids, alkalines, solvents, hydraulic liquids etc. |

| Hydrolysis and microbe resistance | very good - acc. to EN 50363-10-2 + VDE 0207-363-10-2 |

| Weather resistance | very good acc. to HD 605 S1 |

| Ozone resistance | very good acc. to EN 50396 |

| Characteristic impedance | 100Ω ± 10Ω, fulfils the electrical and transmission requirements with high frequency with reference to EN 50288-2-2 (CAT 5e acc. to EN 50173) |

| Mechanical characteristics | the main mechanical characteristics accomplished by the PUR outer sheath are: - high tensile strength - high tear strength (≥ 40 N/mm) - high abrasion resistance - high notch resistance - high transverse stregth |

| Schadstofffrei | acc. to RoHS directive of the European Union |

max. 60 V

core/core 600 V

core/screen 600 V

fixed laying: 5 x d

flexible application: 10 x d

fixed laying: -50/+90 °C

flexible application: -40/+90 °C

short-time use: +125 °C (2000 h)

flame retardant and self-extinguishing acc. to IEC 60332-1-2 + VDE 0482-332-1-2

very good - TMPU acc. to EN 50363-10-2 + VDE 0207-363-10-2

good against acids, alkalines, solvents, hydraulic liquids etc.

very good - acc. to EN 50363-10-2 + VDE 0207-363-10-2

very good acc. to HD 605 S1

very good acc. to EN 50396

100Ω ± 10Ω, fulfils the electrical and transmission requirements with high frequency

with reference to EN 50288-2-2 (CAT 5e acc. to EN 50173)

the main mechanical characteristics accomplished by the PUR outer sheath are:

- high tensile strength

- high tear strength (≥ 40 N/mm)

- high abrasion resistance

- high notch resistance

- high transverse stregth

acc. to RoHS directive of the European Union

Dimensions

| item no. |

No. of cores x cross section |

Largest single wire-ø | Outer-ø ± 10% | Copper figure | Cable weight ≈ |

Ohmic resistance at 20°C max. |

min. breaking load of suspension unit | |

|---|---|---|---|---|---|---|---|---|

| L1531-9010 | (4 x 2 x 22)C + 2 x 22 | 0,34 mm | 9,1 mm | 64,7 kg/km | 110 kg/km | 58,8 Ω/km | 600 N | Send inquiry |

cross section

wire-ø

at 20°C max.

of suspension unit

Other dimensions and colours are possible on request.