High Voltage Measurement Glossary

In the following overview you will find frequently used terms in high-voltage measurement technology and their explanations. If you have any further questions or suggestions, please contact our SAB-Team directly.

The (generally) recognised rules of technology are technical rules or guidelines for the design and execution of structural or technical objects. These are rules that are recognised as theoretically correct and established in science, as well as being known in practice by technicians trained in accordance with the latest state of knowledge and have proven themselves on the basis of continuous practical experience. The generally recognised rules of technology are not identical to standards.

Highest effective value of the direct or alternating voltage that can be permanently applied to an insulation during normal operation.

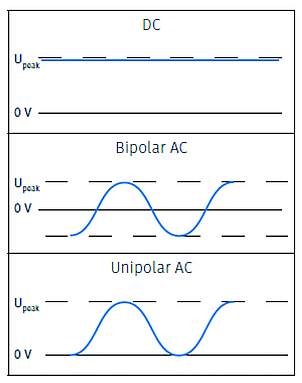

Alternating current (AC) refers to a type of electric current that changes its direction periodically and in constant repetition. Alternating current is often used for electrical energy supply. It flows through high-voltage lines and reaches ordinary house holds via socket.

Conditioned in a way that it can be touched by a standardized test pin. This term could be confused with the term „scoop-proof”.

The indication „scoop-proof” means in connexion with our S HV sensors the following:

The item has been designed and tested in a way that there is no risk of an electric shock for the user if he touches the cable under condition that the measuring tip is conductively connected with a component that does not exceed the indicated nominal voltage. Herewith, it is always indicated until which point or layer safety is guaranteed. Some items have for example a coloured inner sheath that indicates when mechanical wear threatens the safety described before. Other multi pair cables have partial elements. Here the pairwise insulation already fulfils the safety requirements.

Due to the risk to mix it up with the normative term „tangible”, the term „voltage-proof” is preferred for this characteristic as it is not used in standards.

The nominal voltage is the basis of assessment for out items. Certain operational characteristics refer to this nominal voltage.

Constructive precautions at electric operating equipment that protect against hazardous contact with energized components (for example insulation). The term „contact protection“ is related to voltage rating that indicates the upper limit of electric voltage with which measuring equipment can be operated safely. This upper limit (nominal voltage) depends on the operational environment of the measuring accessories.

In connection with SAB HV sensors unipolar is the voltage that in contrast to real direct voltage – does not change sign but has got an alternating value. In fact it is a mixture out of direct and alternating voltage. In contrast to unipolar, bipolar means that the sign of voltage can change.

The dielectric strength (usually specified in kV/mm) of an insulator is the maximum electric field strength that may prevail in the material without a voltage breakdown (arc or spark) occurring. In a statistical series of breakdown voltage tests, this is the lower limit of the measured values.

The breakdown voltage is the voltage required to allow current to flow through an insulator. This results in an electrical voltage breakdown. In a statistical series of breakdown voltage tests, this is the upper limit of the measured values.

Direct current (DC) refers to electrical current whose strength and direction do not change over time. Batteries and solar cells, for example, supply direct current.

An electrical voltage above 1000V AC or 1500V DC is generally referred to as high voltage. In the VDE regulations, standardised voltages up to 1kV are referred to as low voltage and over 1kV as high voltage. In electrical power engineering, further conceptual subdivisions of high voltage into the subterms „medium voltage“, „high voltage“ and „extra-high voltage” are common, although the limits are not standardised. In the context of this glossary, „high voltage“ refers to the 60 kV and 110 kV range for supplying smaller towns, overland supply and the connection of smaller power stations.

Within the range of electrical technology in vehicles we also talk abour high voltage. When the term „high voltage“ (HV for short) is used, it clearly refers to a voltage in motor vehicles that is higher than 25V (AC) or higher than 60V (DC). The reason for this is that the term „high voltage“ clearly indicates the potential danger.

The term HV identification refers to the labelling of the cables and connection components of the HV sensors. The connection component is labelled with an orange bend protection sleeve and a „Danger“ label, the measuring cable with a corresponding identification strip in orange. This signal colour warns of the new sources of danger in hybrid and electric vehicles. The use or marking with the colour orange (known as „high-voltage orange“) can be found in the ISO 6469-3 and ECE-R 100 standards.

Basic insolation:

Insulation of dangerously active parts that ensures basic protection.

Additional insulation:

Independent insulation applied in addition to the basic insulation to ensure protection against electric shock in the event of failure of the basic insulation.

Double insulation:

Insulation consisting of the basic insulation and the additional insulation.

Reinforced insulation:

Insulation that provides protection against electric shock that is not less than the protection provided by the double insulation.

With the „insulated measuring tip”, the bare measuring tip is hermetically sealed. The insulation at the bare point (measuring tip) is stronger than the basic insulation, but weaker than the reinforced insulation. However, it fulfils the criteria for a dielectric strength of 1000V AC and is considered as scoop-proof.

With the „mechanically insulated measuring tip”, the bare measuring tip is provided with additional basic insulation, but this is open on the side of the measuring tip. It offers no protection against accidental contact, but fulfils the criteria for 1000V AC. If the insulation fails, there is no additional protection in the area of the measuring tip.

The leakage distance is the shortest distance along the surface of a solid insulating material between two conductive parts. The leakage distance for measuring accessories means the shortest distance along the surface of an insulating material between a part that is dangerous to touch and a part of the user's body.

The sparking distance in air is defined as the shortest distance in air between two conductive parts.

The purpose of the test finger is to simulate the non-touch ability of active parts by the human finger. The dimensions are specified in EN 61010-031. A distinction is made between rigid test fingers and articulated ones.

Testing voltage is the voltage that a test specimen (connector, cable, other components) can withstand without breakdown or flashover when handled as specified. This voltage is significantly higher than the specified nominal voltage.

Common scales are 2xUnenn + 1000V.

Conformity tests on each individual unit during or after production.

The VDE, originally Verband Deutscher Elektrotechniker (Association of German Electrical Engineers), since 1998 the Association for Electrical Engineering, Electronics and Information Technology is committed to the sciences in these fields and the technologies based on them. The VDE’s work focuses on safety in electrical engineering, the development of recognised rules of technology as national and international standards and the testing and certification of devices and systems.