Construction

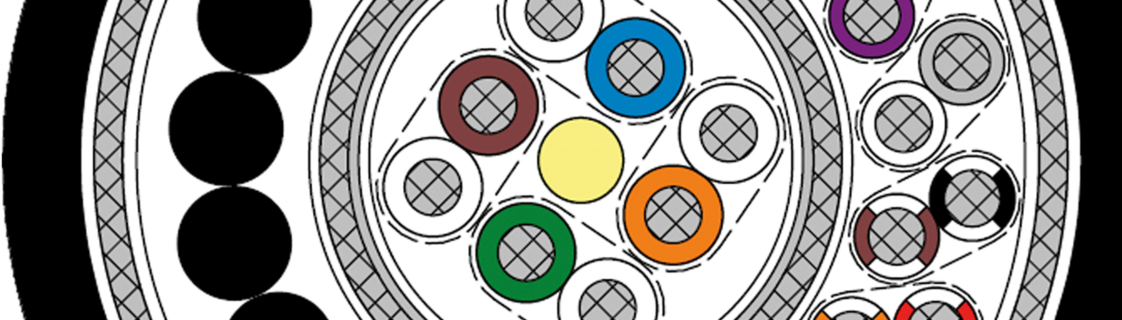

| Dimension | (4 x 2 x 28AWG)Cat. 5e + 8 x 2 x 28AWG + 3 x 28AWG |

|---|---|

| Conductor | bare copper strands, fine wires |

| Insulation | FEP |

| Colour code | 28 AWG: white/black, white/brown, white/red, white/orange, white/yellow

22 AWG: black, red |

| Stranding | 28 AWG: cores twisted to pairs, each pair with drain wire 22 AWG |

| Wrapping | foil |

| Stranding | 28 AWG: cores twisted to pairs |

| Stranding | all elements together in specially adjusted layering, Aramid in the centre |

| Wrapping | foil |

| Screen | tinned copper braiding, optical coverage > 85% |

| Wrapping | tape |

| Sheath material | PUR |

| Sheath colour | black (similar RAL 9005) with mat surface, non-reflective |

(4 x 2 x 28AWG)Cat. 5e +

8 x 2 x 28AWG + 3 x 28AWG

bare copper strands, fine wires

FEP

28 AWG:

white/black, white/brown,

white/red, white/orange,

white/yellow

22 AWG:

black, red

28 AWG: cores twisted to pairs, each pair with drain wire 22 AWG

foil

28 AWG: cores twisted to pairs

all elements together in specially adjusted layering, Aramid in the centre

foil

tinned copper braiding,

optical coverage > 85%

tape

PUR

black (similar RAL 9005)

with mat surface, non-reflective

Technical Data

| Peak operating voltage | max. 60 V |

|---|---|

| Testing voltage | core/core 600 V core/screen 600 V |

| Min. bending radius | fixed laying: 5 x d flexible application: 10 x d |

| Temperature range | fixed laying: -50/+90 °C flexible application: -40/+90 °C short-time use: +125 °C (2000 h) |

| Fire performance | flame retardant and self-extinguishing acc. to IEC 60332-1-2 + VDE 0482-332-1-2 |

| Oil resistance | very good - TMPU acc. to EN 50363-10-2 + VDE 0207-363-10-2 |

| Chem. resistance | good against acids, alkalines, solvents, hydraulic liquids etc. |

| Hydrolysis and microbe resistance | very good - acc. to EN 50363-10-2 + VDE 0207-363-10-2 |

| Weather resistance | very good acc. to HD 605 S1 |

| Ozone resistance | very good acc. to EN 50396 |

| Characteristic impedance | pairs 28 AWG suitable for data transfer acc. to USB 3.0 standard |

| Mechanical characteristics | the main mechanical characteristics accomplished by the PUR outer sheath are: - high tensile strength - high tear strength (≥ 40 N/mm) - high abrasion resistance - high notch resistance - high transverse stregth |

| Absence of harmful substances | acc. to RoHS directive of the European Union |

max. 60 V

core/core 600 V

core/screen 600 V

fixed laying: 5 x d

flexible application: 10 x d

fixed laying: -50/+90 °C

flexible application: -40/+90 °C

short-time use: +125 °C (2000 h)

flame retardant and self-extinguishing acc. to IEC 60332-1-2 + VDE 0482-332-1-2

very good - TMPU acc. to EN 50363-10-2 + VDE 0207-363-10-2

good against acids, alkalines, solvents, hydraulic liquids etc.

very good - acc. to EN 50363-10-2 + VDE 0207-363-10-2

very good acc. to HD 605 S1

very good acc. to EN 50396

pairs 28 AWG suitable for data transfer acc. to USB 3.0 standard

the main mechanical characteristics

accomplished by the PUR outer sheath are:

- high tensile strength

- high tear strength (≥ 40 N/mm)

- high abrasion resistance

- high notch resistance

- high transverse stregth

acc. to RoHS directive of the European Union

Dimensions

| item no. |

No. of cores x cross section |

Largest single wire-ø | Outer-ø ± 10% | Copper figure | Cable weight ≈ |

Ohmic resistance at 20°C max. |

min. breaking load of suspension unit | |

|---|---|---|---|---|---|---|---|---|

| L1531-9012 | (4 x 2 x 28) + 8 x 2 x 28 + 3 x 28 | 0,09 / 0,15 mm | 7,8 mm | 62,1 kg/km | 92 kg/km | 223,8 Ω/km | 230 N | Send inquiry |

cross section

wire-ø

at 20°C max.

of suspension unit

Other dimensions and colours are possible on request.