Application

The SABdynamic 900 Control is a flexible control cable that is characterized by its robustness, oil resistance and flame retardancy. Thanks to its high flexibility, it is particularly suitable for continuous use in drag chain applications with high bending stresses and long travel distances. The polyurethane (PUR) jacket ensures high abrasion resistance and durability even under demanding conditions. With a temperature range of -50 °C to +90 °C, the cable remains reliable even at extreme temperatures.

Outstanding features

- UL/cUL recognized

- PWIS uncritical (PWIS = paint-wetting impairment substances)

- extremely large temperature range

- halogen-free

- high abrasion resistance

- suitable for long travel distances in drag chains

- small bending radius

- small outer diameter

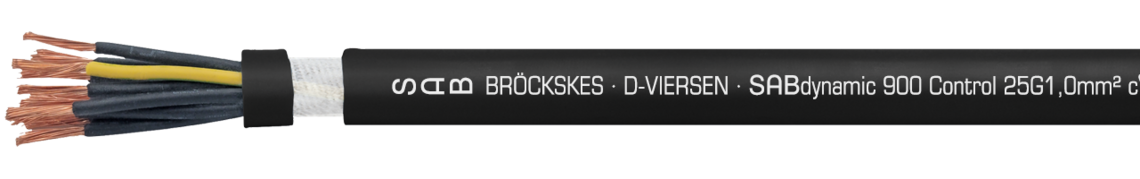

Construction

| Conductor | bare copper strands acc. to IEC 60228, VDE 0295, class 6 |

|---|---|

| Insulation | SABIX® |

| Colour code | black cores with consecutive numbers acc. to EN 50334 + VDE 0293-334, green-yellow earth wire from 3 cores |

| Stranding | specially adjusted layering with non-woven tape over each layer |

| Sheath material | PUR with mat surface |

| Sheath colour | black (RAL 9005) |

bare copper strands acc. to IEC 60228, VDE 0295, class 6

SABIX®

black cores with consecutive numbers acc. to EN 50334 + VDE 0293-334, green-yellow earth wire from 3 cores

specially adjusted layering with non-woven tape over each layer

PUR with mat surface

black (RAL 9005)

Technical Data

| Nominal voltage | Uo/U 300/500 V |

|---|---|

| Voltage UL/cUL | 600 V |

| Testing voltage | core/core 2000 V |

| Min. bending radius | fixed laying: 3 x d flexible application: 7,5 x d bending cycles: > 10 Mio. |

| Temperature range | DIN VDE fixed laying: -50/+90 °C flexible application: -50/+90 °C

UL/cUL: up to +80 °C |

| Halogen-free | acc. to IEC 60754-1 + VDE 0482-754-1 |

| Fire performance | flammhemmend und selbstverlöschend nach IEC 60332-1-2 + VDE 0482-332-1-2, cUL FT1, FT2 |

| Oil resistance | sehr gut - TMPU nach EN 50363-10-2 + VDE 0207-363-10-2 |

| Chem. resistance | good against acids, alkalines, solvents, hydraulic liquids etc. |

| Continuous Flexibility | very good |

| Sunlight resistance | acc. to HD 605 |

| Ozone resistance | acc. to DIN EN 50396 |

| Salt water resistance | nach UL 1309 |

| Absence of harmful substances | gemäß RoHS-Richtlinie der Europäischen Union |

Uo/U 300/500 V

600 V

core/core 2000 V

fixed laying: 3 x d

flexible application: 7,5 x d

bending cycles: > 10 Mio.

DIN VDE

fixed laying: -50/+90 °C

flexible application: -50/+90 °C

UL/cUL: up to +80 °C

acc. to IEC 60754-1 + VDE 0482-754-1

flammhemmend und selbstverlöschend nach IEC 60332-1-2 + VDE 0482-332-1-2, cUL FT1, FT2

sehr gut - TMPU nach EN 50363-10-2 + VDE 0207-363-10-2

good against acids, alkalines, solvents, hydraulic liquids etc.

very good

acc. to HD 605

acc. to DIN EN 50396

nach UL 1309

gemäß RoHS-Richtlinie der Europäischen Union

Dimensions

| item no. | Screen |

No. of cores x cross section |

Largest single wire-ø |

Outer-ø ± 10% | Copper figure | Cable weight ≈ | |

|---|---|---|---|---|---|---|---|

| L09000210 | unscreened | 2 x 1,00 mm² | 0,16 mm | 5,3 mm | 19,2 kg/km | 37 kg/km | Send inquiry |

| L09002510 | unscreened | 25 x 1,00 mm² | 0,16 mm | 13,8 mm | 240,0 kg/km | 307 kg/km | Send inquiry |

| L09000315 | unscreened | 3 x 1,50 mm² | 0,16 mm | 6,2 mm | 43,2 kg/km | 64 kg/km | Send inquiry |

| L09000525 | unscreened | 5 x 2,50 mm² | 0,16 mm | 9,3 mm | 120,0 kg/km | 160 kg/km | Send inquiry |

| L09012510 | screened | 25 x 1,00 mm² | 0,16 mm | 14,3 mm | 336,9 kg/km | 377 kg/km | Send inquiry |

cross section

wire-ø

± 10%

Other dimensions and colours are possible on request.