Application

These cables are suitable for fixed installation and flexible use, e.g. in mechanical and plant engineering under medium mechanical loads in dry, damp and wet rooms.

Outstanding features

- UL recognized, CSA approval

- low capacity construction

- very good EMC characteristics

- halogen-free

- very high flexibility

- suitable for cable tracks

- very good oil resistance

- very long service life

- adhesion-free installation

- PWIS uncritical (PWIS = paint-wetting impairment substances)

- flexible at low temperatures

Additional information

- EMC optimized due to low capacity and ground-symmetrical cable construction

- high symmetry and low couplin for low-loss power transmission on frequency converters

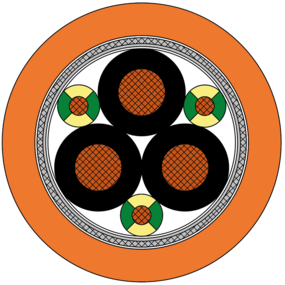

Construction

| Conductor | bare copper strands acc. to IEC 60228, VDE 0295, class 6 |

|---|---|

| Insulation | special polymer |

| Colour code | black cores with consecutive numbers acc. to EN 50334 + VDE 0293-334 and a green-yellow earth wire |

| Stranding | in layers |

| Wrapping | non-woven tape |

| Screen | alu foil and tinned copper braiding |

| Sheath material | PUR |

| Sheath colour | orange (RAL 2003) |

bare copper strands acc. to IEC 60228, VDE 0295, class 6

special polymer

black cores with consecutive numbers acc. to EN 50334 + VDE 0293-334 and a green-yellow earth wire

in layers

non-woven tape

alu foil and tinned copper braiding

PUR

orange (RAL 2003)

Technical Data

| Nominal voltage | Uo/U 0.6/1 kV |

|---|---|

| Voltage UL/cUL | 1000 V |

| Testing voltage | core/core 4000 V core/screen 4000 V |

| Min. bending radius | fixed laying: 5 x d flexible application: 10 x d |

| Temperature range | DIN VDE fixed laying: -50/+90 °C flexible application: -40/+90 °C UL/cUL: up to +80°C |

| Halogen-free | acc. to IEC 60754-1 + VDE 0482-754-1 |

| Fire performance | flame retardant and self-extinguishing acc. to IEC 60332-1-2 + VDE 0482-332-1-2, cULus FT1, FT2 |

| Oil resistance | very good - TMPU acc. to EN 50363-10-2 + VDE 0207-363-10-2 |

| Chem. resistance | good against acids, alkalines, solvents, hydraulic liquids etc. |

| Weather resistance | very good |

| Absence of harmful substances | acc. to RoHS directive of the European Union |

Uo/U 0.6/1 kV

1000 V

core/core 4000 V

core/screen 4000 V

fixed laying: 5 x d

flexible application: 10 x d

DIN VDE

fixed laying: -50/+90 °C

flexible application: -40/+90 °C

UL/cUL: up to +80°C

acc. to IEC 60754-1 + VDE 0482-754-1

flame retardant and self-extinguishing acc. to IEC 60332-1-2 + VDE 0482-332-1-2, cULus FT1, FT2

very good - TMPU acc. to EN 50363-10-2 + VDE 0207-363-10-2

good against acids, alkalines, solvents, hydraulic liquids etc.

very good

acc. to RoHS directive of the European Union

Abmessungen

| item no. | Dimension |

Largest single wire-ø | Outer-ø ± 10% | Copper figure | Cable weight ≈ | |

|---|---|---|---|---|---|---|

| L08350315 | 3 x 1,50 mm² + 3 G 0,25 mm² | 0,16 mm | 9,2 mm | 76,8 kg/km | 121 kg/km | Send inquiry |

| L08350325 | 3 x 2,50 mm² + 3 G 0,50 mm² | 0,16 mm | 11,5 mm | 138,2 kg/km | 202 kg/km | Send inquiry |

| L08350340 | 3 x 4,00 mm² + 3 G 0,75 mm² | 0,16 mm | 12,7 mm | 197,0 kg/km | 264 kg/km | Send inquiry |

| L08350360 | 3 x 6,00 mm² + 3 G 1,00 mm² | 0,21 mm | 14,2 mm | 263,7 kg/km | 341 kg/km | Send inquiry |

| L08350370 | 3 x 10,00 mm² + 3 G 1,50 mm² | 0,21 mm | 16,5 mm | 430,7 kg/km | 523 kg/km | Send inquiry |

| L08350380 | 3 x 16,00 mm² + 3 G 2,50 mm² | 0,21 mm | 19,8 mm | 649,4 kg/km | 772 kg/km | Send inquiry |

| L08350390 | 3 x 25,00 mm² + 3 G 4,00 mm² | 0,21 mm | 22,8 mm | 973,2 kg/km | 1096 kg/km | Send inquiry |

| L08350395 | 3 x 35,00 mm² + 3 G 6,00 mm² | 0,21 mm | 26,4 mm | 1345,8 kg/km | 1526 kg/km | Send inquiry |

| L08350396 | 3 x 50,00 mm² + 3 G 10,0 mm² | 0,31 mm | 30,7 mm | 1926,7 kg/km | 2180 kg/km | Send inquiry |

wire-ø

Weitere Abmessungen und Farben auf Anfrage.