Application

For flexible use on mobile GPUs, in PIT systems, on frequency converters and as a flexible extension for operating lengths over 25 metres.

Outstanding features

- low capacity insulation

- very flexible and smooth handling

- very good installation in narrowest spaces

- good resistance

- low wear

- with wear indicator

Additional information

Current carrying capacity

With reference to LV112-3 and based on an application-related current-time profile and the following operating conditions:

- ambient temperatures up to max. 52°C

- two phases of the same colour connected to one conductor

- other cores (35mm² bl and 1mm²) unloaded

- laying individually on or on surfaces

- 286 A for max. 10 min.

- 325 A for max. 5 min.

- 364 A for max. 10 s

- 520 A for max. 2 s

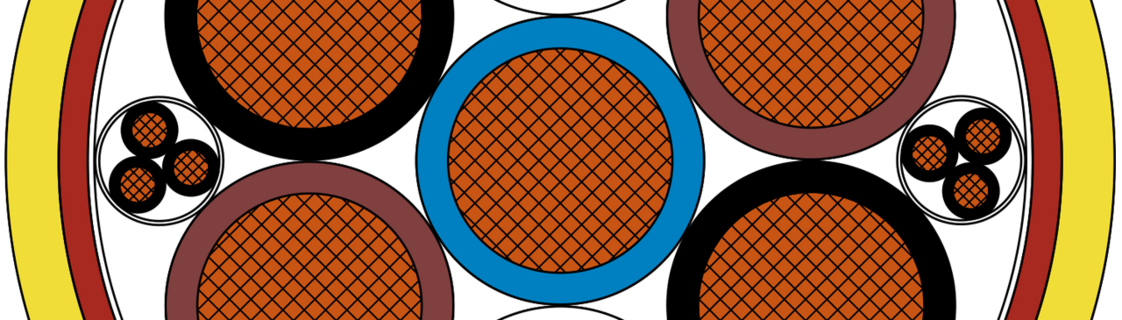

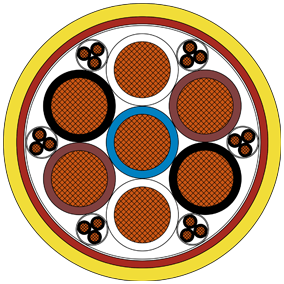

Construction

| Conductor | bare copper strands, fine wires acc. to IEC 60228 class 5 |

|---|---|

| Insulation | SABIX® |

| Colour code | 1,0 mm²: black with numbers 25,0 resp. 35,0 mm²: blue, 2 x (white, brown, black) |

| Stranding | 1,0 mm²: cores twisted to triples, wrapped with non-woven tape. All elements optimized stranded in layers, wrapped with non-woven tape |

| Inner sheath | special polymer, red |

| Outer sheath | special polymer, yellow |

bare copper strands, fine wires acc. to IEC 60228 class 5

SABIX®

1,0 mm²: black with numbers

25,0 resp. 35,0 mm²: blue, 2 x (white, brown, black)

1,0 mm²: cores twisted to triples, wrapped with non-woven tape.

All elements optimized stranded in layers, wrapped with non-woven tape

special polymer, red

special polymer, yellow

Technical data

| Nominal voltage | 1,0 mm²: Uo/U max. 115/200 V 25,0 resp. 35,0 mm²: Uo/U 0,6/1 kV |

|---|---|

| Testing voltage | core/core 4000 V AC 50 Hz |

| Min. bending radius | fixed laying: 4 x d flexible application: 6 x d for one single bend: 3 x d |

| Temperature range | fixed laying: -40/+70 °C flexible application: -30/+70 °C |

| Fire performance | acc. to IEC 60332-1-2 |

| Oil resistance | good - acc. to EN 50290-2-22 |

| Chemical resistance | good against acids, alkalines, solvents, hydraulic liquids, etc. |

| Weather resistance | good |

| Salt water resistance | good |

| Hydrolysis and microbial resistance | good |

| Ozone resistance | good |

| Abrasion | acc. to UL 2556-2021 and JIS C3005 |

| Fuel resistant | petrol, diesel and kerosene (Jet A-1) |

| Mechanical resistance | characteristics of the outer sheath: - good tensile strength - good abrasion resistance - good notch resistance |

| Absence of harmful substances | acc. to RoHS directive of the European Union |

1,0 mm²: Uo/U max. 115/200 V

25,0 resp. 35,0 mm²: Uo/U 0,6/1 kV

core/core 4000 V AC 50 Hz

fixed laying: 4 x d

flexible application: 6 x d

for one single bend: 3 x d

fixed laying: -40/+70 °C

flexible application: -30/+70 °C

acc. to IEC 60332-1-2

good - acc. to EN 50290-2-22

good against acids, alkalines, solvents, hydraulic liquids, etc.

good

good

good

good

acc. to UL 2556-2021 and JIS C3005

petrol, diesel and kerosene (Jet A-1)

characteristics of the outer sheath:

- good tensile strength

- good abrasion resistance

- good notch resistance

acc. to RoHS directive of the European Union

Dimensions

| item no. |

No. of cores x cross section | Approx. outer-ø | Copper figure | Cable weight ≈ |

Ohmic resistance max. Ω/km | |

|---|---|---|---|---|---|---|

| L34000100 | 7 x 25,0 mm² + 6 x 3 x 1,0 mm² | min. 38,0 mm - max. 39,9 mm | 1853 kg/km | 2757 kg/km | 25,0 mm²: 0,78 Ω/km | 1,0 mm²: 19,5 Ω/km | Send inquiry |

| L34000101 | 7 x 35,0 mm² + 6 x 3 x 1,0 mm² | min. 42,0 mm - max. 44,0 mm | 2525 kg/km | 3235 kg/km | 35,0 mm²: 0,554 Ω/km | 1,0 mm²: 19,5 Ω/km | Send inquiry |

| L34000103 | 7 x 35,0 mm² + 6 x 4 x 1,0 mm² | min. 42,0 mm - max. 44,0 mm | 2583 kg/km | 3320 kg/km | 35,0 mm²: 0,554 Ω/km | 1,0 mm²: 19,5 Ω/km | Send inquiry |

| L34000102 | 7 x 25,0 mm² + 6 x 4 x 1,0 mm² | min. 40,0 mm - max. 41,9 mm | 1910 kg/km | 2820 kg/km | 25,0 mm²: 0,78 Ω/km | 1,0 mm²: 19,5 Ω/km | Send inquiry |

cross section

max. Ω/km

Other dimensions and colours are possible on request.