"Hidden Needs" in the design of transmission cables for digital surgical microscopes and cameras.

Why "hidden" requirements of customers are often important in the development of electrical cables? Marc Gerlatzek, product manager for the medical technology division at SAB Bröckskes, explains what is meant by "hidden needs".

The use of digital microscopes and cameras, both in conventional and hybrid operating rooms, ensures the transmission of high-resolution images. Whether established 3D and 4K visualization or augmented reality, the focus for uninterrupted use is on the cable's ability to transmit brilliant and noise-free signals.

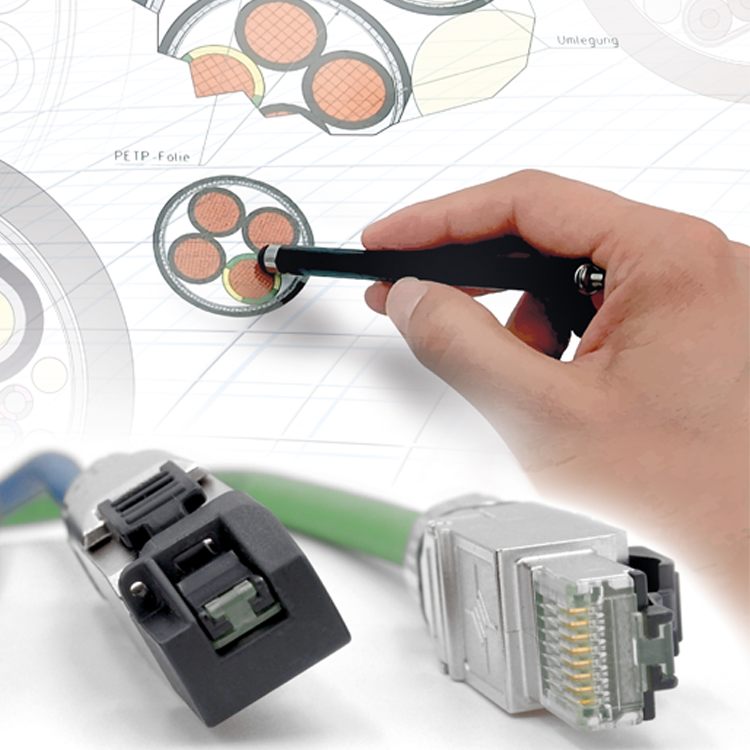

In many medical applications imaging devices may require extreme maneuverability, integrated recording components, built-in light management and co-viewing systems. As a result of these requirements, cables designed for imaging devices usually are performing multiple tasks to unite different signal transmissions, such as USB and Ethernet, in the smallest possible spaces.

"Certainly, such an implementation requires a high level of know-how and sometimes presents challenges for our engineers" says Marc Gerlatzek, product manager for the medical technology division at SAB Bröckskes GmbH & Co KG. "Our work is not finished with precision based cable design alone, at SAB we must consider a holistic approach which only works with direct customer dialog. Having direct dialog with our customers allows us to minimize any unforeseen application requirements”

For example, the following may seem less significant when designing imaging cables however often they become "hidden needs" which directly influences the performance of these cables. It’s important to discuss these “hidden needs” prior to design and production.

Examples

- the device connection via a ceiling supply or an articulated arm that has to move in all axes

- the use of computer-assisted robotics

- the intended connectors and connection geometries

- expected electrical interference in the integrated operating room

The expertise on the individual application possibilities requires a sufficient depth of knowledge from the cable manufacturer, ideally gathered from experiences, successes and certainly setbacks. The ultimate consideration however, is still the technical integration of all known features and hidden needs in one cable throughout the finished cable assembly.

Cable production possible from 100 m

In order to make such customer-specific modifications possible, the cable specialist SAB relies on close customer contact. Due to the fact that all cable production is carried out exclusively on serial machines and lines, each prototype is at the same time suitable for presentation to the notified body. On these cable productions, which are possible from 100 m, measurements can be carried out under real conditions on both the cables and the cable assemblies. The subsequent exchange of knowledge and - if required - the subsequent practical implementation in design features are elementarily important for a continuously successful application.

Customized cable assembly

Over the past few years, SAB's offering has more and more complete cable assembly. "Many of our customers want a complete solution consisting of cables and plugs. We have continuously expanded the segment of cable assembly in recent years, which ultimately corresponds to the general market development and requirements of end users. As a result, we can now offer every customer exactly the connection solution they need."