Pt100 Resistance thermometers (RTD) change their electrical resistance in dependence on the temperature or, in other words, resistance thermometers use the fact that the electrical resistance of an electrical conductor varies with changing temperature.

In order to collect the output signal, the resistance is fed with a constant measuring current and the created voltage drop is measured. Platinum RTDs Pt 100, Pt 500 and Pt 1000. Pt100 platin measuring resistances are used as measuring probes. They are standardized acc. to DIN EN 60751. Their resistance is 100 Ω at 0°C.

The most different construction types of platinum resistance thermometers are applied in industrial measuring technique.

Our standard mineral insulated resistance thermometers are delivered for measuring ranges from - 50 °C up to + 400 °C and - 50 °C up to + 600 °. This indicated measuring range refers to the allowed temperature at the measuring tip of the resistance thermometer. In those temperature ranges the Pt 100 resistance thermometer is situated in a fixed characteristic line. Deviations from this characteristic line, also called basic values, are approved according to 2 tolerance classes A and B. Limit deviations please see "Basic Values of Mineral Insulated Resistance Thermometers". Platinum resistance thermometers are the most accurate sensors and show an excellent long-time stability. Due to the chemical insensitiveness of the platinum, the risk of contamination by oxidation and other chemical influences is reduced.

Advantages of platinum resistance thermometers:

- high chemical reistance

- consistency

- long-term stability

- easy treatment

The standard value for the accuracy of platinum resistance thermometers is approx. -/+ 0,5 % of the measured temperature. They are applied in nearly all fields of industrial temperature measurement.

A reliable temperature measurement requires a most exact adaptation to the corresponding process. This statement can be applied for thermocouples as well as for resistance thermometers. Thermocouples in contrast to resistance thermometers are more simple, more robust, mostly cheaper, applicable in a broad temperature range, and have small measuring points. Due to the punctual measurement with thermocouples, they have a quicker response time than resistance thermometers.

Resistance thermometers, however, have a high accuracy and reproducibility and the measuring points are a little bit bigger than those of thermocouples. Due to the planar measurement with resistance thermometers for reasons of construction, they show a slower response time.

Technical Description of Mineral Insulated Resistance Thermometers

1. General Information on Pt100 Temperature Sensors

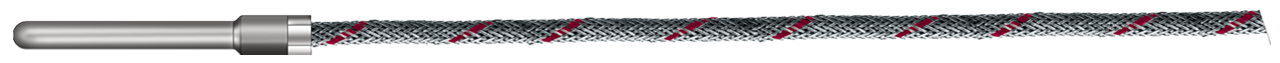

In general SAB BRÖCKSKES furnishes its insulated resistance thermometers with Platinum Pt 100 acc. to DIN EN60751. On request, we are also able to deliver mineral insulated resistance thermometers with Pt 500, Pt 1000. We recommend the use of Platinum RTDs due to their high level of stability and consistency. Mineral insulated resistance thermometers are often used for temperature measurement in containers, tubes, appliances, and machines. They are applied whenever the flexible mounting and dismounting of the measuring probes are of great importance. Please note that mineral insulated resistance thermometers are only appropriate for low pressures and small flow rates.

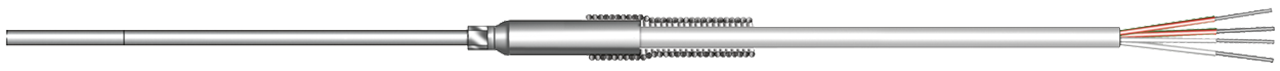

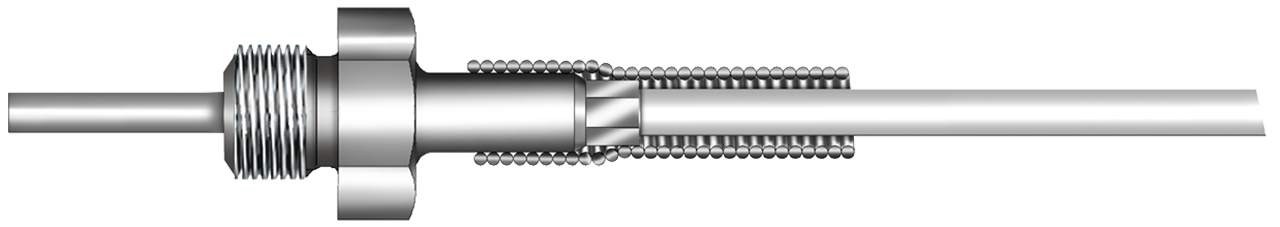

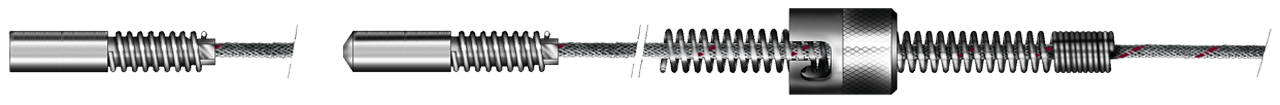

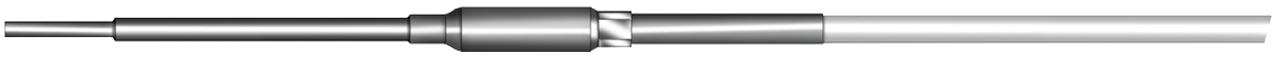

2. Construction of Pt100 Resistance Thermometers

The flexible and thin special steel tube of sheath contains 2, 4 or 6 inner wires which are pressed into magnesium oxide. The measuring resistance is connected to the inner wires and embedded into magnesium oxide powder. In general, material no. 1.4541 is used as sheath material.

3. Response Times of Pt100 Sensors

Mineral insulated Pt100 thermometers have short response times and react quickly onto changing temperatures. You will find the approximate values in the table response times of thermocouples and resistance thermometers.

Do you have any questions about our products? Your direct line to our experts! Contact

Download: Basic information resistance thermometers

![[Translate to English:] Widerstandsthermometer Pt100 [Translate to English:] Widerstandsthermometer Pt100](/fileadmin/user_upload/Relaunch/Inhalt/Technische_Daten/Temperaturmesstechnik/Allgemeine_Informationen/Widerstandsthermometer.png)